Optical alignment using the radius of curvature measurement from HASO4 sensor

Why do we use the radius of curvature for optical alignment?

Measuring the wavefront radius of curvature is one way to get the best optical aligment which is used in several applications such as:

-

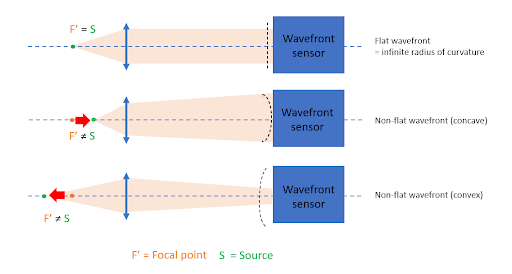

- Collimate beams: ensuring that collimators or collimating optics (small or large) are precisely aligned, outputting a wavefront as flat as possible (see Figure 1).

-

- Optics conjugaison of imaging systems: AR/VR headsets conjugate the LCD screen to a virtual plane as far as possible and within the specs provided by their customers.

Using a wavefront sensor to measure the radius of curvature

Shack-Hartmann wavefront sensors are excellent tools to easily measure the wavefront radius of curvature and therefore, do the optical alignment. Using an array of micro-lenses in front of a CMOS or CCD camera, these sensors can provide a real time measurement of the wavefront radius of curvature, at the speed of the camera with excellent accuracy and with minimum alignment.

The HASO SWIR wavefront sensor manufactured by Imagine Optic can provide this measurement with a refresh rate close to 100 Hz, and an accuracy of ±0.002m-1 diopter on the 900 – 1700 nm spectral band.

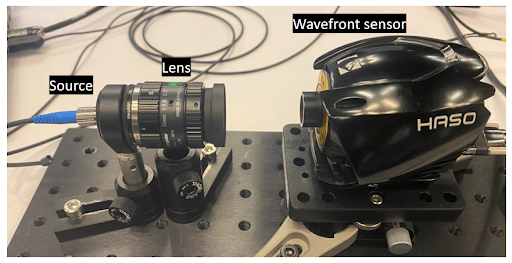

This allows the user to adjust the alignment of their optical system and maximize the radius of curvature value very comfortably. Below is an example of a 1550 nm single mode fiber point source, being collimated by a 25 mm lens (see Figure 2).

Beam collimation example

Here is an example of a beam collimation. The lens focus is being adjusted in order to collimate the beam in real time (see Figure 2).

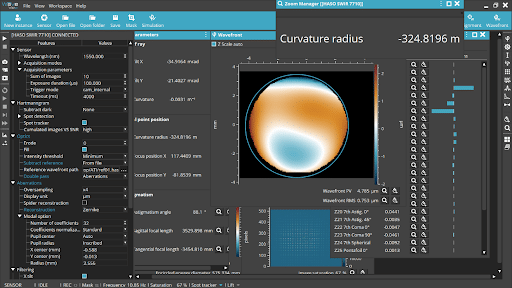

Once the radius of curvature is maximum, the beam is collimated. Thanks to the real time measurement provided by the wavefront sensor, the user was able to manually collimate the point source to a distance of about 300 m (see Figure 3).

The video below shows how easily the beam collimation is, and therefore the optical alignment, when using a wavefront sensor.

Both hardware and software provide an instant access to visualization of the wavefront curvature, given with an accuracy of ±0.002m-1 or diopter. As Radius = 1/curvature, ±0.002m-1 is equivalent to a point source located about 300m away, which is considered a very good collimation by most industrial companies and research centers. It is important to notice that HASO wavefront sensors can provide this measurement not just for close to collimated wavefronts, they can also measure the curvature of very diverging or converging wavefronts, up to F/5, with extreme accuracy, thanks to a proprietary calibration and reconstruction algorithm.

Extending to other applications and cases (large beams and white light sources)

In the case shown above, the beam is about the same size as the input pupil of the HASO wavefront sensor (about 11 mm diameter). The light source is also a point source, single wavelength which allows us to use a very simple set- up i.e. a direct measurement with a HASO wavefront sensor.

However, radius of curvature measurements can also be precisely performed on large beams, or with sources that have large spectral bands.

– Using a calibrated RFLEX LA system for example, it is possible to measure a beam up to 150 mm.

– On AR/VR headsets, the broadband light from the LCD can be used for the measurement.

Conclusion

Using Haso wavefront sensors, we can :

-

- align optics in real time by measuring the radius of curvature (at the speed of wavefront sensor);

-

- collimate an optical system with a radius of curvature > 200 m in most cases;

-

- measure curvature (1/R) with accuracy better than ±0.002m-1 with HASO SWIR and even lower with other sensor models;

-

- measure small beams with a wavefront sensor directly , but also larger beams using the RFLEX LA system.

For more information about Shack-Hartmann wavefront sensors, and to discover the full line of Imagine Optic products and accessories for wavefront metrology, click Here.

To read our application note on wavefront sensing, click Here.