Calibrating each individual bolometer of an uncooled microbolometer focal plan array is mandatory to achieve a uniform image when looking at a uniform reference such as a black body. This is due to the behavior of each bolometer (or pixel) being inherently different from one another. The non-uniformity of a LWIR detector is impacted by various parameters such as the sensor temperature, the sensor gain, the sensor exposure time, the sensor frame rate, the optics used etc.

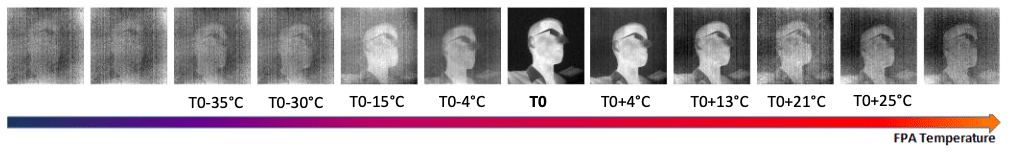

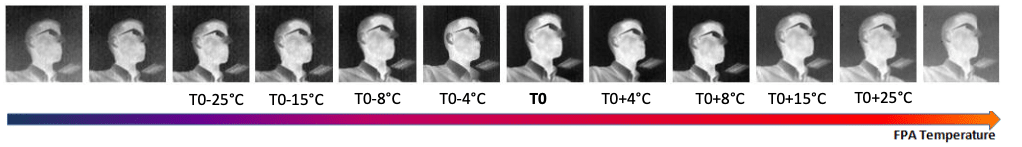

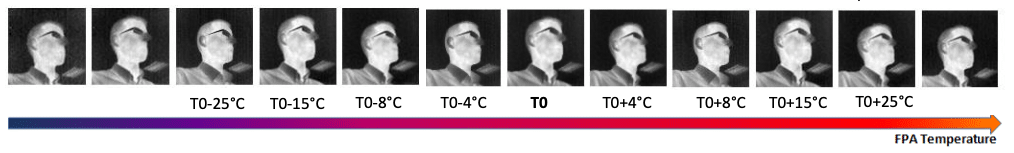

Different methods of calibration can be used depending on the application. A classical 2-point NUC (non-uniformity correction) consists of adjusting each pixel value by an offset (acquired using a ‘cold’ reference from a black-body) and a multiplicator/gain value (acquired using a ‘warm’ reference from a black-body) such that after the correction is applied, the response of the entire array is homogenous and the image quality optimal. A 2-point NUC correction produces an RNU (residual non-uniformity) that is optimal for the calibration temperature (T0) but that quickly degrades as the detector temperature moves away from T0 as shown in the figure below:

Depending on the application, there are several ways to compensate for the changes in image quality as the detector temperature drifts due to environmental conditions changing (daytime vs nighttime etc).

Method 1: The shutter-based approach

The use of a mechanical shutter introduced either between the sensor and the lens or in front of the lens allows additional 1-point NUC corrections, thus increasing the latitude around the original T0 . Additional 1-point NUC corrections enables operation at other sensor temperatures and can be done as many times as necessary. Though efficient, mechanical shutters have several drawbacks:

-

- Loss of information as the camera is blinded during the shutter period

-

- Additional bulk and weight to the camera

-

- Additional cost

-

- Additional power consumption from the electric motor

-

- Decreased reliability inherent to the mechanical moving parts

-

- Noise as the shutter opens/closes.

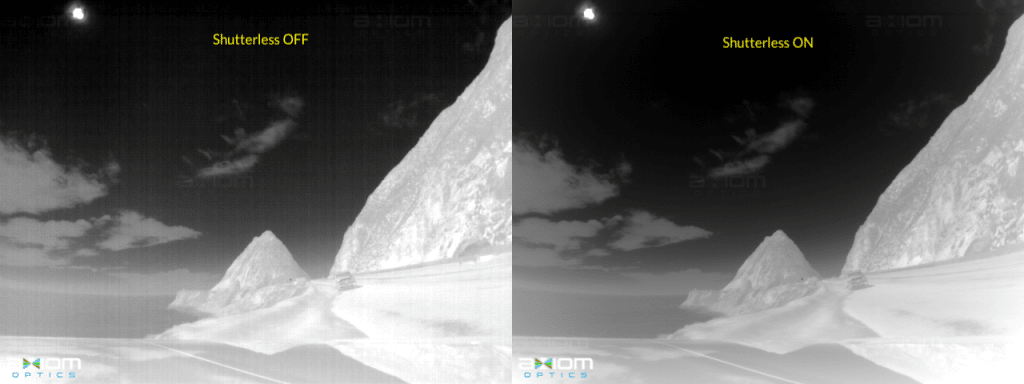

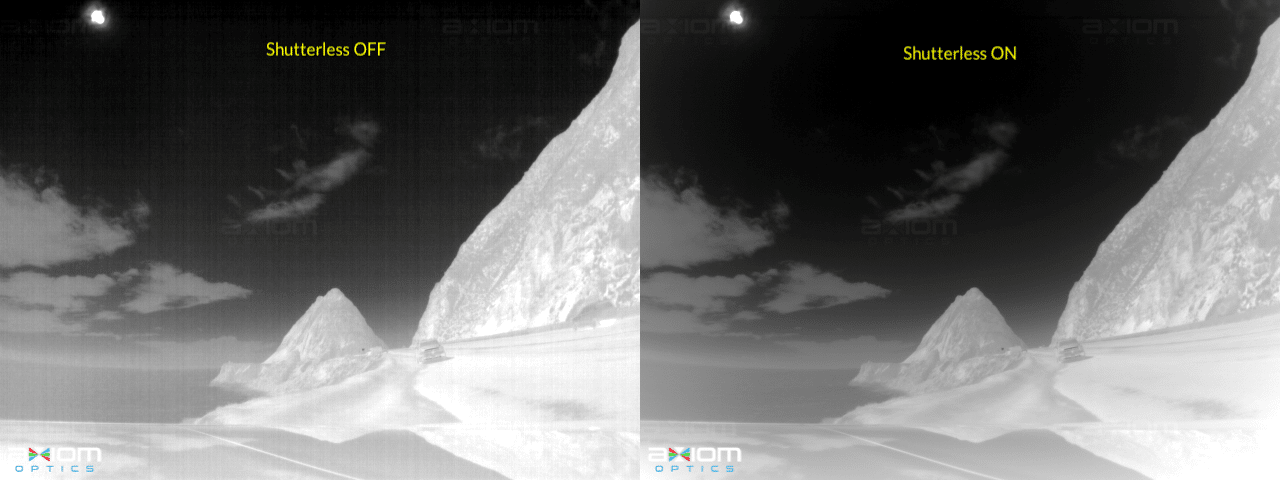

Method 2: Shutterless operation

All our LWIR thermal cameras, whether with processing on the host controller (thermal modules) or with on-board processing (engine cores), are able to store a number of shutterless calibrations (up to 8 depending on the models).

https://www.axiomoptics.com/products/irlugx1m3-sxga-thermal-camera-module/