Photographers use light to make art, while scientists, from medical researchers to wildlife biologists, use it to make discoveries. Meanwhile, military and surveillance cameras use light and heat to detect and remediate threats.

It turns out that Superman’s X-ray vision isn’t entirely a fantasy: some cameras can “see” what’s inside a plastic bottle or detect bruising on a piece of fruit that isn’t visible to the naked eye. These specially designed cameras use materials sensitive to radiation emitted or reflected in specific wavelengths within the infrared spectrum, but various types are available. Learn the differences between SWIR, MWIR, and LWIR cameras.

The Infrared Spectrum

SWIR Cameras

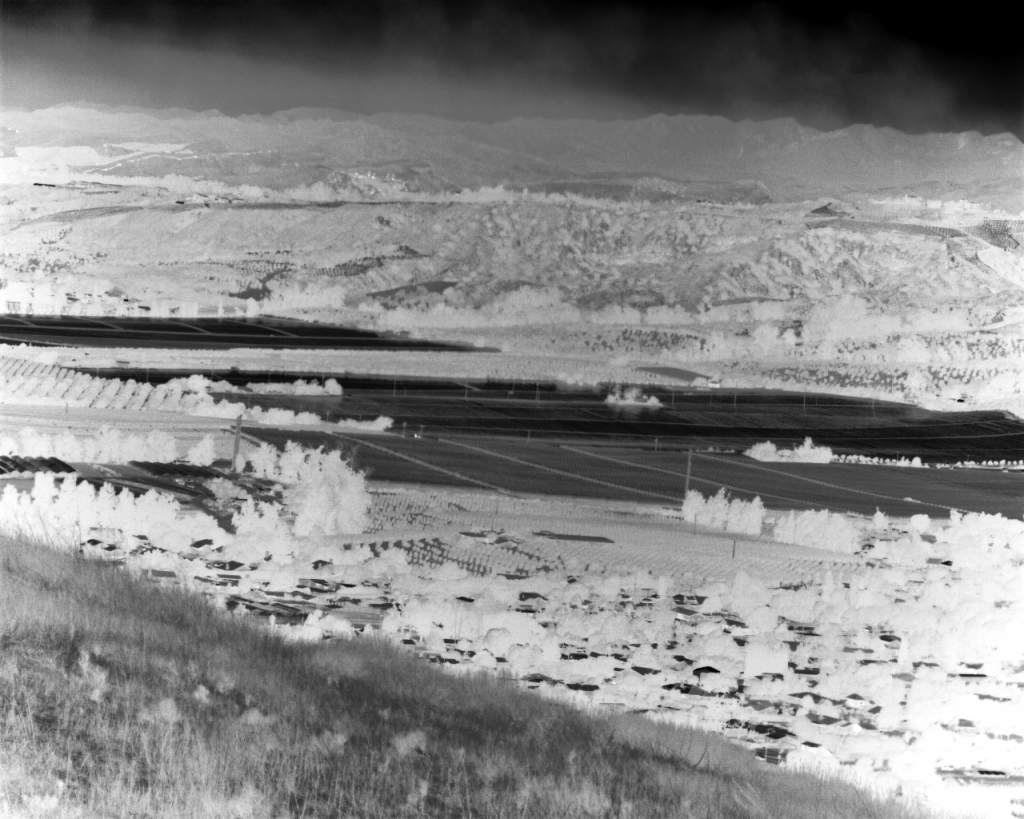

Short-Wave Infrared (SWIR) cameras, operating within the 1 to 3 micrometer wavelength range, distinguish themselves from Mid-Wave Infrared (MWIR) and Long-Wave Infrared (LWIR) cameras by their reliance on reflected light rather than thermal emissions. While MWIR cameras (3–5 micrometers) and LWIR cameras (8–14 micrometers) are designed to detect heat radiated from objects—making them ideal for spotting hot machinery or living beings in complete darkness—SWIR cameras capture infrared light reflected off surfaces, much like how visible light cameras operate. This fundamental difference allows SWIR cameras to excel in scenarios where thermal contrast is minimal or irrelevant, such as identifying material composition, detecting moisture, or imaging through obscurants like haze and smoke that are transparent to SWIR wavelengths but block visible light and sometimes challenge thermal bands. Additionally, SWIR cameras typically employ sensors made from materials like InGaAs, which don’t require the cryogenic cooling often necessary for MWIR cameras or the uncooled microbolometers common in LWIR systems, offering a practical trade-off in terms of size, power consumption, and operational simplicity.

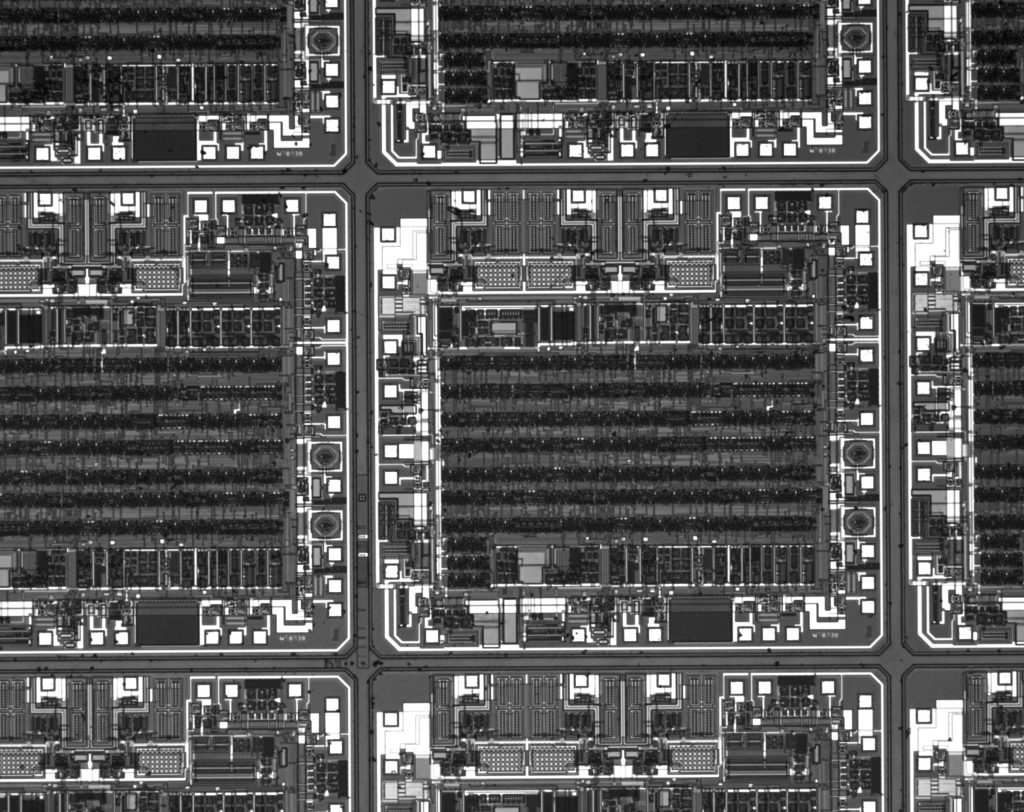

The imaging capabilities of SWIR cameras further set them apart from MWIR and LWIR systems in terms of resolution and environmental adaptability. Because SWIR wavelengths are shorter than those in the MWIR and LWIR bands, SWIR cameras can achieve higher spatial resolution, producing sharper images that are critical for detailed inspection tasks, such as identifying defects in semiconductor wafers or reading text through packaging. In contrast, LWIR cameras, with their longer wavelengths, often suffer from diffraction-limited resolution, resulting in fuzzier images, while MWIR cameras offer a middle ground but are still tailored more for thermal contrast than fine detail. SWIR cameras also shine in low-light conditions when paired with active illumination (e.g., SWIR lasers), a flexibility MWIR and LWIR cameras lack since they depend on passive heat signatures and can’t leverage external light sources effectively. This makes SWIR cameras uniquely suited for applications like surveillance, night vision, and counterfeit detection, where MWIR and LWIR cameras would be less effective due to their focus on thermal rather than reflective properties.

Cost, complexity, and application scope further highlight the distinctions between SWIR, MWIR, and LWIR cameras. SWIR cameras, while historically expensive due to the cost of InGaAs sensors, have become more accessible with advancements like Sony’s SenSWIR technology, which reduces pixel size and integrates visible-to-SWIR imaging, broadening their commercial appeal. MWIR cameras, however, often require sophisticated cooling systems—such as Stirling coolers—to maintain sensor sensitivity, driving up both cost and power demands, which confines them largely to high-end military and industrial uses like missile guidance or gas leak detection. LWIR cameras, on the other hand, benefit from uncooled designs that make them cheaper and more portable, dominating markets like consumer thermal imaging, firefighting, and building diagnostics, but they lack the material-penetrating and high-resolution capabilities of SWIR systems. Thus, SWIR cameras carve out a niche where precision, versatility, and non-thermal imaging are paramount, contrasting with the heat-centric strengths of MWIR and LWIR cameras that cater to different operational needs.

MWIR Cameras

Mid-Wave Infrared (MWIR) cameras, operating in the 3 to 5 micrometer wavelength range, are engineered to detect thermal emissions from objects, setting them apart from Short-Wave Infrared (SWIR) and Long-Wave Infrared (LWIR) cameras through their unique sensitivity to higher-temperature sources. Unlike SWIR cameras (1–3 micrometers), which rely on reflected light and excel at imaging through haze or identifying material properties, MWIR cameras capture heat signatures, making them ideal for applications like tracking jet engines, exhaust plumes, or industrial machinery where elevated temperatures create stark contrasts against cooler backgrounds. In contrast to LWIR cameras (8–14 micrometers), which are tuned to detect ambient heat from objects at terrestrial temperatures—such as humans or buildings—MWIR cameras offer superior performance in scenarios involving hotter targets, as their shorter wavelengths align with the peak emissions of high-temperature objects per Planck’s law. This thermal focus, however, often necessitates cooled detectors, typically made from materials like indium antimonide (InSb) or mercury cadmium telluride (MCT), distinguishing MWIR systems from the uncooled sensors of LWIR and the room-temperature InGaAs sensors of SWIR cameras.

The technological demands and imaging characteristics of MWIR cameras further differentiate them from SWIR and LWIR systems. MWIR cameras frequently require cryogenic cooling—using systems like Stirling coolers—to reduce thermal noise and maintain sensitivity, a stark contrast to SWIR cameras, which operate without such complexity, and LWIR cameras, which leverage uncooled microbolometers for simplicity and portability. This cooling requirement increases the size, weight, power consumption, and cost of MWIR cameras, positioning them as specialized tools for high-stakes applications like military targeting, missile defense, and gas leak detection, where their ability to resolve hot objects through atmospheric windows (e.g., 3–5 µm) is unmatched. While SWIR cameras provide higher resolution due to shorter wavelengths and excel in reflective imaging, and LWIR cameras offer broader accessibility with fuzzier, diffraction-limited images, MWIR strikes a balance with moderate resolution and exceptional thermal contrast for mid-range temperatures, though it lacks SWIR’s material-penetrating versatility or LWIR’s suitability for low-temperature ambient scenes.

Application scope and environmental performance also underscore the distinctions between MWIR, SWIR, and LWIR cameras. MWIR cameras shine in environments where thermal differentiation of hot objects is critical, such as detecting chemical vapors (e.g., methane) that absorb specific MWIR wavelengths or tracking fast-moving targets in defense scenarios, capabilities that SWIR cameras can’t replicate due to their non-thermal nature and that LWIR cameras struggle with due to their focus on cooler, slower-emitting objects. However, MWIR’s reliance on cooling systems limits its practicality compared to LWIR’s lightweight, uncooled designs, which dominate consumer and first-responder markets like firefighting, or SWIR’s adaptability to active illumination for night vision and industrial inspection. Additionally, MWIR’s atmospheric transmission window makes it less affected by water vapor than LWIR, which can be attenuated by humidity, yet it doesn’t match SWIR’s ability to penetrate smoke or certain solids. Thus, MWIR cameras occupy a specialized niche, bridging the gap between SWIR’s reflective precision and LWIR’s ambient thermal breadth with a focus on high-temperature thermal imaging.

LWIR Cameras

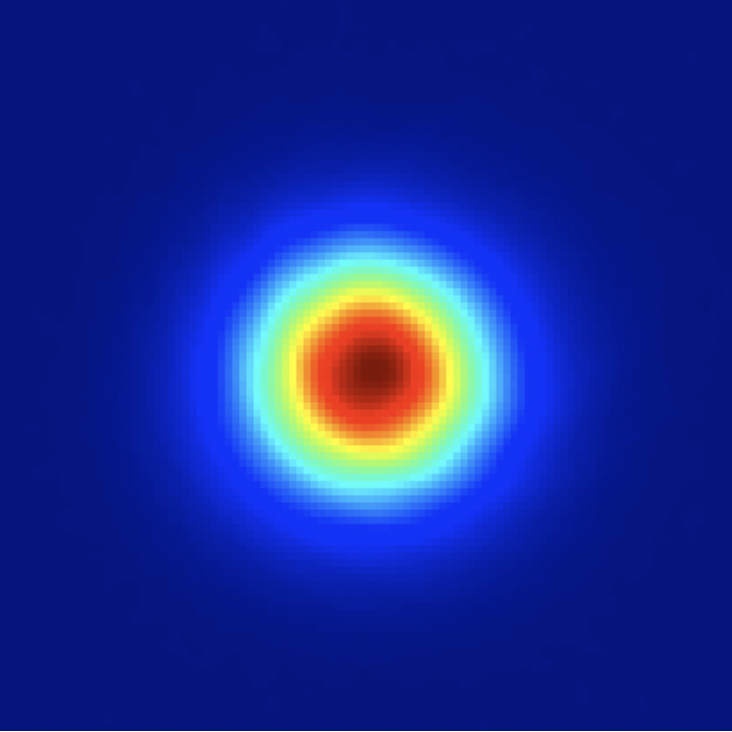

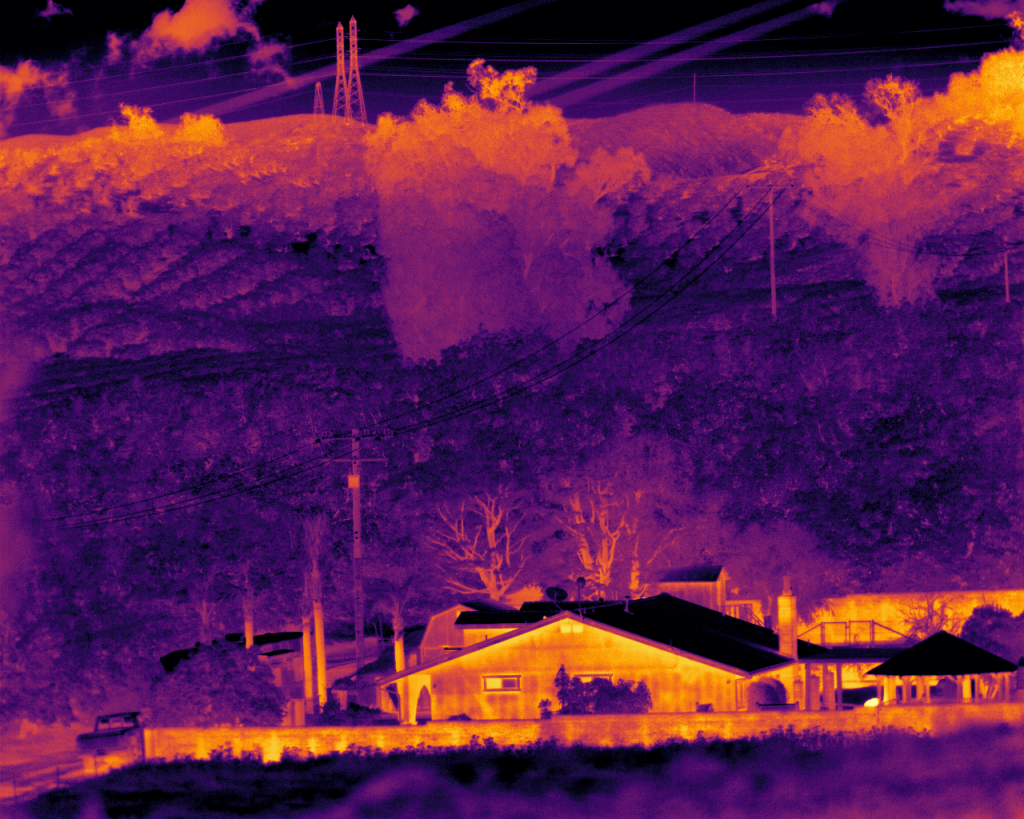

Long-Wave Infrared (LWIR) cameras, operating within the 8 to 14 micrometer spectral band, are optimized to detect blackbody radiation emitted from objects at terrestrial ambient temperatures (approximately 250–350 K), leveraging the peak emissivity of such sources as dictated by Wien’s displacement law (λ_max ≈ 10 µm at 300 K). This distinguishes them fundamentally from Short-Wave Infrared (SWIR) cameras (1–3 µm), which detect reflected photons rather than thermally emitted ones, and Mid-Wave Infrared (MWIR) cameras (3–5 µm), which are tuned to shorter wavelengths corresponding to higher-temperature emitters (e.g., 600–1000 K). LWIR cameras typically employ uncooled vanadium oxide (VOx) or amorphous silicon (a-Si) microbolometers, which measure changes in electrical resistance induced by absorbed infrared radiation, offering a noise-equivalent temperature difference (NETD) typically in the range of 30–50 mK. In contrast, SWIR systems rely on indium gallium arsenide (InGaAs) photodiodes with quantum efficiencies exceeding 70% in their band, while MWIR cameras necessitate cryogenically cooled mercury cadmium telluride (MCT) or indium antimonide (InSb) detectors to suppress thermal noise, achieving NETDs below 20 mK but at the cost of increased system complexity.

The optical and detection properties of LWIR cameras impose distinct technical trade-offs compared to SWIR and MWIR systems. The longer wavelengths of LWIR result in a diffraction-limited spatial resolution governed by the Rayleigh criterion (θ ≈ 1.22λ/D), yielding larger minimum resolvable angles for a given aperture size (e.g., ~12 µrad for a 100 mm lens at 10 µm) compared to SWIR (~3 µrad at 2 µm) or MWIR (~6 µrad at 4 µm), thus limiting LWIR to coarser imagery despite typical focal plane array (FPA) pixel pitches of 12–17 µm. This contrasts with SWIR’s finer resolution, enabled by shorter wavelengths and smaller pixel pitches (e.g., 5 µm in Sony’s SenSWIR), and MWIR’s moderate resolution with cooled FPAs often at 15–30 µm pitches. LWIR’s uncooled operation eliminates the need for Stirling-cycle coolers (common in MWIR, consuming 5–10 W) or active illumination (optional in SWIR), reducing power draw to ~1–2 W and enabling compact designs. However, LWIR’s broadband sensitivity renders it susceptible to atmospheric attenuation by water vapor and CO2 (absorption peaks at 13–14 µm), unlike MWIR’s clearer 3–5 µm window or SWIR’s relative immunity to thermal atmospheric effects, restricting LWIR’s range in humid conditions.

From a radiometric and application perspective, LWIR cameras excel in passive thermal imaging of low-emissivity scenes, detecting radiance differences (ΔL ≈ εσT^4) where emissivity (ε) and temperature (T) variations are subtle, such as in human detection (ΔT ≈ 5–10 K) or insulation faults. SWIR cameras, reliant on external or natural SWIR-band illumination (e.g., nightglow at 1.5–1.7 µm), lack this thermal sensitivity but penetrate materials like silicon or glass (transparent below 3 µm) and resolve spectral reflectance signatures for material classification, unfeasible with LWIR’s thermal focus. MWIR cameras, optimized for Planck curves peaking at 3–5 µm (e.g., 700 K sources), outperform LWIR in high-contrast thermal scenes (e.g., gas plumes with specific absorption lines at 3.3 µm) but falter at ambient temperatures where LWIR’s longer wavelengths align with maximum radiance. LWIR’s uncooled architecture supports cost-effective, ruggedized systems versus MWIR’s high-cost cooled designs or SWIR’s specialized InGaAs arrays, positioning LWIR as the dominant choice for broadband thermal imaging in automotive, security, and industrial diagnostics, despite its limitations in resolution and atmospheric propagation compared to its shorter-wavelength counterparts.

How To Choose Your Infrared Camera

Selecting an infrared camera—whether Short-Wave Infrared (SWIR, 1–3 µm), Mid-Wave Infrared (MWIR, 3–5 µm), or Long-Wave Infrared (LWIR, 8–14 µm)—requires a systematic evaluation of the application’s radiometric, environmental, and operational requirements, as each spectral band offers distinct physical and technical advantages. The first step is defining the target’s thermal characteristics and the desired imaging mode. SWIR cameras detect reflected photons, necessitating an illumination source (natural, like nightglow, or artificial, like a 1.55 µm laser), and are insensitive to thermal emission, making them ideal for non-thermal tasks such as material identification (e.g., distinguishing plastics via reflectance spectra) or imaging through obscurants like smoke or silicon (transparent below 3 µm). In contrast, MWIR and LWIR cameras capture emitted thermal radiation, with MWIR excelling at higher-temperature targets (600–1000 K, λ_max ≈ 3–5 µm per Wien’s law) like jet engines or gas plumes, and LWIR aligning with ambient temperatures (250–350 K, λ_max ≈ 10 µm) for detecting humans or passive objects. If the goal is thermal contrast of hot sources, MWIR is preferable; for ambient scenes in darkness, LWIR is optimal; and for reflective, non-thermal imaging, SWIR is the choice.

Next, consider the environmental conditions and optical requirements, as atmospheric transmission and resolution needs vary across bands. SWIR wavelengths propagate well through haze and certain materials but require high-resolution optics (e.g., f/1.4 lenses with 5 µm pixel pitches) to leverage their short-wavelength advantage (θ ≈ 1.22λ/D yields ~3 µrad at 2 µm), delivering crisp imagery for applications like semiconductor inspection. MWIR benefits from a relatively clear atmospheric window (3–5 µm), with minimal absorption by water vapor compared to LWIR, and offers moderate resolution (~6 µrad at 4 µm) suitable for long-range detection of hot targets, though its cooled detectors (e.g., InSb, NETD < 20 mK) demand stable conditions. LWIR, while versatile in total darkness or fog (due to thermal emission reliance), suffers from atmospheric attenuation by H2O and CO2 (13–14 µm) and lower resolution (~12 µrad at 10 µm) due to diffraction, making it less effective for fine detail or humid environments but ideal for short-range, broadband thermal mapping with uncooled microbolometers (NETD ≈ 30–50 mK). Assess range, obscurants, and detail needs: SWIR for penetration and precision, MWIR for mid-range thermal clarity, LWIR for close-in ambient robustness.

Finally, weigh practical constraints like cost, power, and system complexity against performance goals. SWIR cameras, historically pricey due to InGaAs sensors (e.g., $5,000–$15,000), are becoming more accessible (e.g., Sony SenSWIR), with low power needs (~1–2 W) and no cooling, but may require illumination hardware. MWIR cameras, reliant on cryogenic cooling (e.g., Stirling coolers, 5–10 W), are expensive (>$10,000) and bulky, limiting them to high-budget, specialized uses like military targeting or spectroscopy (e.g., CH4 detection at 3.3 µm). LWIR cameras, leveraging uncooled designs (<$1,000–$5,000), are the most cost-effective and portable (1–2 W), dominating consumer and industrial markets despite their resolution trade-offs. Budget and deployment logistics are thus critical: choose SWIR for niche reflective imaging with moderate investment, MWIR for premium thermal performance in controlled settings, or LWIR for affordable, rugged thermal utility. Match the camera to the mission—thermal vs. reflective, temperature range, distance, and resources—to ensure optimal results.