Today cameras are equipped with Focal Plane Array (FPA) detectors. There are currently 2 types of FPA detectors used in commercial IR cameras: photon (quantum) detectors (or photodetectors) and thermal detectors, commonly referred as microbolometers.

How does a microbolometer work?

A microbolometer is a thermal detector that operates by measuring the temperature of a material with a high temperature coefficient of resistance, called a thermistor. The thermistor is usually made of thin layer of vanadium oxide (VOx) or amorphous silicon (a-Si), both of which have high sensitivity to infrared radiation. As infrared radiation (Ra) hits the IR absorber of the thermistor, its temperature (Tabs) changes and the heat generated then changes the resistor (Rptc). The thermistor is connected to a resistor and a source of electrical current, and the voltage across the resistor is measured to determine the resistance of the thermistor. The readout circuit amplifies this voltage change and converts it into a digital signal (S) that can be used to create an image. The microbolometer is typically composed of a large number of pixels, each of which has its own thermistor and readout circuit. By measuring the resistance of each thermistor, an infrared image can be created that shows the distribution of temperature across the scene being viewed.

S = f (Tabs, RPTC , τ MB, Ra)

Microbolometers must be stabilised at about room temperature using a TE cooling or compensated for drift thanks to dynamic NUC mapping.

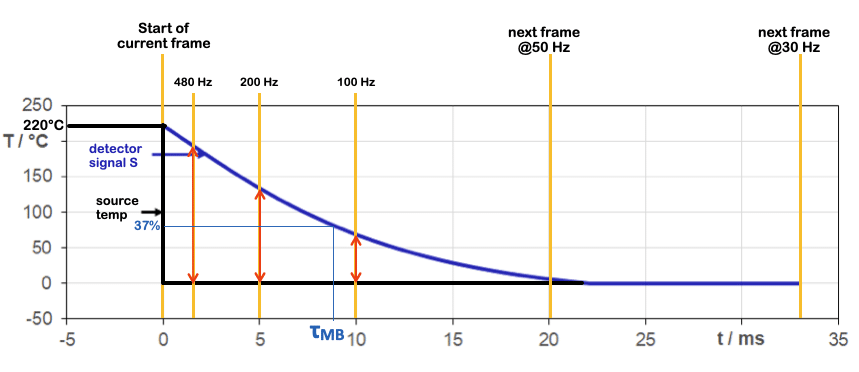

The time constant (τ MB) of a microbolometer is caused by the heating-up and cooling down of the IR absorber. The time constant corresponds to the time corresponding to a signal change of 63% of its final value. For a modern microbolometer, this time is between 8 and 10 ms. The final value is reached after about 2 to 3τ MB or about 20-25 ms.

As a consequence, a frame rate higher than 30 to 50 Hz of a microbolometer will decrease the measurement range dynamics as the signal does not have the time to go back to baseline.

How does a photon quantum detector work?

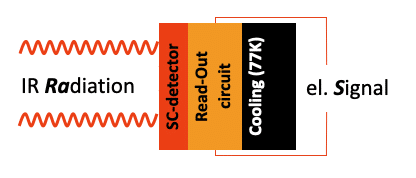

A photon quantum detector (or photodetector) is designed to detect individual photons of light. It works by absorbing the photon in a semiconductor material, which triggers the emission of an electrical signal that can be amplified and detected. Photon quantum detectors are very sensitive and can detect very low levels of light. They are generally made of InGaAs, InSb, MCT, T2SL, SLS materials cooled down to 77K by integrated stirling coolers. New High Operating Temperature (HOT) photon detectors such as XBn or nBn allow cooling at 110K only, thus reducing the cooling capacity and therefore power consumption.

The pixel of a photodetector array is electronically shuttered by opening or shorting the integration capacitor. The time constant τ SC of an electronics shutter is in the range of 10 ns.

S = f (τ SC, Ra)

As a result, quantum detectors are intrinsically faster than microbolometer. Instead of changing the temperature of the pixels as in a microbolometer detector, quantum detectors convert photon energy to electrons in the semiconductor by elevating them above the detector energy band-gap into the conduction band.

Side-by-side comparison

| Cooled Quantum Detectors | Uncooled Microbolometers | |

| Materials | InGaAs, InSb, MCT, T2SL, SLS | a-Si, VOx |

| Spectral range | SWIR, MWIR, LWIR | LWIR |

| Thermal sensitivity | typically ≤ 25 mK | typically ≤ 40 mK |

| Cooling | Stirling @ ~77K ºK | Uncooled |

| Stability | Very high | Acceptable |

| Homogeneity | Very high | Range of quality available |

| Time resolution | Integration time ~1 µm to > 20 ms | thermal constant ~ 10ms |

| Max FPS | up to 105,000 | ~30-60 Hz |

| Long-term operation | Lifetime >10,000 hours | Maintenance-free |

| Acquisition Mode | Global shutter / Snapshot | Rolling shutter / Line-by-line |